2025 was the most challenging year on the farm I’ve had yet, featuring substantial growing pains associated with the larger acres and scale-up of equipment to accommodate them. It was a year of several firsts, and a year of the most timely rains I can remember. The crop yields were good overall, even if the prices weren’t.

January started with a snowstorm that caught me in Hays at the Kansas Auctioneers Association convention. It was fun to finally come home to find the boys playing on the ice at the artesian well just as I used to when I was their age. Starting in January and continuing over the course of the spring, the band would spend several sessions in the studio working on a record of cover songs that will be released this coming spring after one final studio session in January 2026. In late January, I had the joy of being the announcer for the school spelling bee in which Callan was a participant.

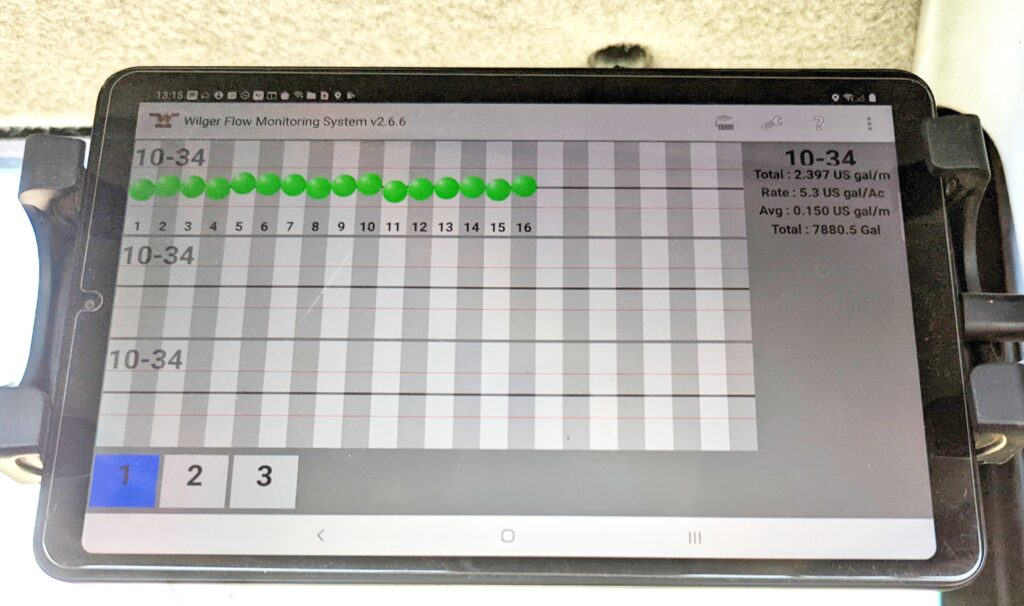

In February we were delighted to learn that Wayne had decided to return to Kansas and would be staying with us for the foreseeable future. Diane and I got to spend Valentine’s Day picking him up at the airport. Two days later, we dragged Wayne to The Book of Mormon in Wichita, along with some other friends, making sure he would immediately begin to question his decision to stay with us. Later in February, I made a run to Iowa to pick up some floater tires for the sprayer, as I wanted tires as wide as possible to avoid compaction when applying spring fertilizer on the wheat. Diane and I made a quick trip to Manhattan to a sold-out Bramlage to attend our first college women’s basketball game.

March found me topdressing wheat and Wayne working on waterproofing and painting the basement. We took everyone to Arkansas on spring break to visit Joan and Eric and let the kids enjoy the Scott Family Amazeum science center in Bentonville as well as their first trip to a Dave and Buster’s. Later in March, I took delivery of a new-to-me air seeder to replace the old Crustbuster drill.

April and May were busy months that found me planting my first corn as well as a large number of soybean acres and some full season milo. We had good moisture, so the crops came up quickly. We had a large rain around Easter, so some acres had standing water to cause drown-outs in some soybeans. The wet spring led to a late harvest, so we had time in June to work on the shop. Wayne did a great job in the northeast corner, cleaning it and applying epoxy before we installed pallet racking and additional lights. Once the combine rolled, Wayne proved crucial running the grain cart on some of the new acres that would be nearly impossible to cut efficiently without it.

July was a pretty tight scramble to finish wheat harvest and get the double-crop milo planted in time. The boys enjoyed getting to pick and eat their first ears of field corn. Wayne continued working on the basement, finally encasing the last of the asbestos floor tile adhesive under a layer of leveling concrete.

August kicked off with our fifth annual South x Sharon music festival, by far our largest yet — we had nine acoustic acts and four bands from about 1 p.m. to 11 p.m.! We found time in August to take a quick trip to Grand Lake in Oklahoma to spend some time on the water. Diane and I ran up to Victoria to Herzog Fest where my old friend Blaine Younger was playing, and he was kind enough to have me come up and help sing the last song with him. It was great to catch up after many, many years!

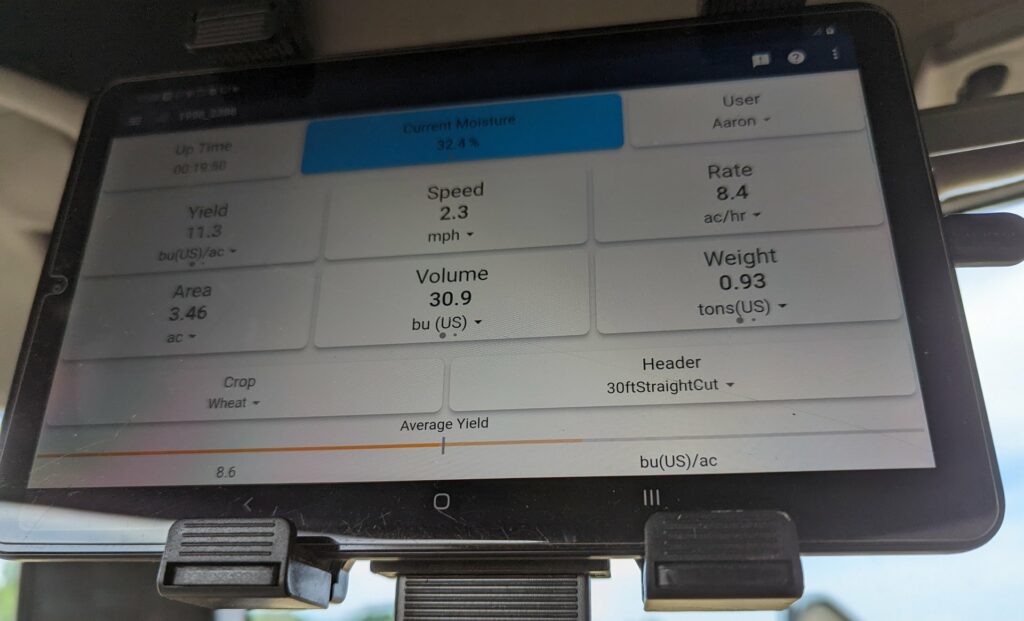

September was our first corn harvest and it was a great experience. I sure picked a good year to try my first corn — the timely rains all spring had the corn looking like it was irrigated. I learned a lot, and was thankful to have Wayne’s help on the grain cart and Diane’s father Ed running the trucks for the majority of harvest. Diane and Wayne still found time in September to paint the kitchen, with help from the boys, as I moved back and forth between the corn and soybean fields.

October continued corn and soybean harvests. I spent what little time I had out of the field working on getting the new air seeder ready for wheat. We also took delivery of a new-to-us car for Diane — a 2022 Ford Escape plug-in hybrid. We’ve always wanted an electric car for her commute, and buying one sight-unseen from a dealer in Detroit was so much less stressful than going to a dealership in person that I don’t think I’ll ever buy a car locally again.

November finally found me putting wheat in the ground. It was a slow, awkward start, but I quickly became proficient with the new air seeder — and have a laundry list of improvements and repairs to make before next season. Diane had unexpected surgery in early November to remove her gallbladder. Dad always loved his blue Kenworth trucks, and I finally found a deal on a 1999 T800 to replace my old, red semi.

The milo was finally dry enough to start cutting in early December. The full season milo had been ready for a while, but I just couldn’t get to it with the more-urgent wheat planting and soybean cutting. I’d been diagnosed with a hernia in July and delayed the surgery — yes, we asked and there’s no “his and hers” discount on laparoscopy — to the last of December in order to get as much farming done as possible. I realized that I made a mistake not hiring someone to cut my full season milo for me, because the yield loss in not getting to it in time would have more than paid to hire it cut. Recognizing that I would turn into a pumpkin on December 29, and not wanting to make the same mistake again, I hired someone to custom harvest my milo at Pixley. It was the first time since I’ve been farming that I hired a custom cutter, and it was the smartest decision I made this year. I spent Christmas on the combine, with the air conditioner running due to the hot weather and, thanks to Wayne’s help switching between the grain cart and running the second combine, finished late on December 27 in time for me to empty the trucks the following day before the surgery on December 29.

While I produced more than twice the amount of grain than any previous year on record, I was also mentally wrecked with the long hours and frustrations from weather-induced delays in operations — to say nothing about the high repair and input costs and comparatively low grain prices. All in all, it was a year of learning. For that, if nothing else, I’m ever thankful.

As I write this review in the middle of January, having taken the last two weeks completely off and away from the farm as I’ve recovered from the surgery, I’m feeling great and am once again excited about 2026 and beyond!